50

|

CERECDOCTORS.COM

|

QUARTER 2

|

2015

C A S E S T U D Y

| | |

B Y D A N I E L VA S Q U E Z , D . D . S .

in-office, computer-aided design and manufacturing (CAD/CAM) technologies

are enabling dentists to provide

their patients with advanced treatment options when various restorations are indicated, including inlays, onlays, and crowns,

among others.

1,2

Esthetic Cementation of In-office

CAD/CAM Crowns Adjacent to Direct

Bulk-fill Composite Restorations

Several restorative materials can be used with these systems

(e.g., lithium disilicate, composite, all-ceramic), depending on

the functional and esthetic requirements of the case.

1,2

When the

restoration design capabilities of today’s CAD/CAM software are

combined with scientifically proven materials, restorations that

fit well and demonstrate enhanced marginal integrity can be effi-

ciently and cost-effectively created.

3,4

In particular, the CEREC in-office system enables same-day

preparation, design and delivery of precisely fitting and esthetic,

full-coverage crown restorations.

5,6

The CEREC digital impres-

sion component (CEREC Omnicam) captures detailed and

accurate images, without the need for traditional impression

materials. Additionally, the design software allows clinicians to

review a tooth, preparation and/or restoration design as if they

were viewing conventional models.

6

However, to maximize the benefits of CAD/CAM technologies,

using materials that can withstand the milling process and be

produced to full contour is necessary. Ideally, the material should

enable placement with adhesive bonding or conventional cemen-

tation, and luting materials that provide enhanced cementation

and adhesion for strong and durable bonds should be selected.

Fortunately, a millable lithium disicliate material, IPS e.max

CAD, demonstrates 400 MPa of strength, lifelike optical prop-

erties, and suitability for full-coverage crowns, veneers, inlays/

onlays, and other restorations.

7

Additionally, a combination

of adhesive luting materials is also available and can be used to

simplify predictable CAD/CAM restoration placement.

8-10

For example, predictable and long-lastingbonds between the all-

ceramic material and preparation can be achieved by first chemi-

cally conditioning restoration surfaces using a silanating agent

(Monobond Plus). Then, to enhance efficiency without sacrificing

bond strength, a single-component, light-cured universal adhe-

sive (Adhese Universal) that is compatible with all etching tech-

niques (e.g., self-etch, selective enamel- etch and total-etch) can

be placed in a precise and convenient manner. Finally, to ensure

harmonious shade matching to adjacent natural teeth or direct

composite restorations, a light- and dual-curing adhesive luting

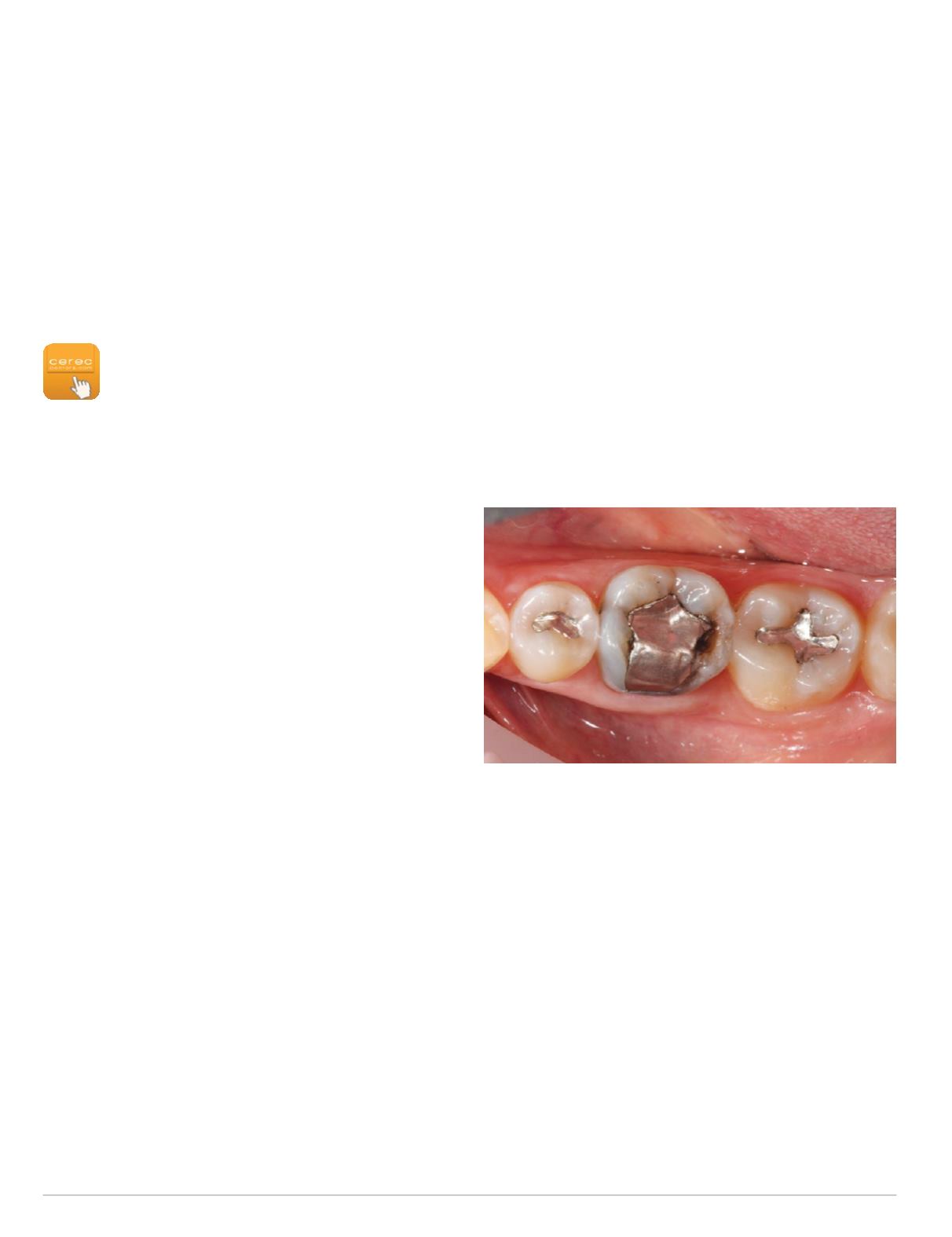

Fig. 1: Preoperative view showing defective amalgam restorations that

had been placed more than 10 years ago

composite (Variolink Esthetic) with color-neutral shades can be

used. This cement’s “Effect” shade system enables seamless shade

matching, yet also facilitates brightening or darkening of the

restoration as needed.

This becomes significantly important when in-office restora-

tions will be placed adjacent to direct, bulk-fill composite restora-

tions and/or over a composite crown build-up. With an esthetic

adhesive luting cement that contains a reactive and patented

Ivocerin light initiator, exceptional shade stability can be realized

in combination with fast and reliable light polymerization.

CASE PRESENTATION

A female patient presented with concerns about old amalgam

restorations that had been placed more than 10 years ago (Fig. 1).

She requested that the unaesthetic amalgams be replaced with