25

milling units and a brand new furnace called the “CEREC Speed-

Fire.” In this article, I will review the workflow in detail with a

clinical case. But first, let me describe the two features that are

important, the milling and the new furnace:

•

milling:

TheMCX andMCXL Practice Labmilling units now

have the option for dry milling capabilities. What this means is

that it can mill all the traditional materials that CEREC offers in

a “wet environment” (the same as it has always done). It also has

the ability tomill zirconia in a “dry environment” with the aid of

a newevacuation unit that is attached to themilling unit.Milling

zirconia dry has advantages when it comes to sintering time

(it doesn’t have to be dried, which lowers the firing cycle). This

will be described below. It should be noted that all the current

wet milling units can mill (carbides) or grind (diamonds)

zirconia in a wet environment. Current users will NOT have

to buy a new milling unit to participate in the new workflow.

Milling or Grinding in a wet environment will only add 10 to 12

minutes to the sintering time (additional drying cycle).

•

cerec speedfire:

The “magic” of the entire process is the new

furnace. A revolutionary accomplishment that allows you to not

only speed-sinter zirconia, but also run a stain/glaze cycle. You

read that right… a single furnace for both sintering and glazing

restorations! If you mill zirconia dry, the sintering time is only

about 15 minutes; if you mill/grind wet, the process is about

27 minutes. After you sinter the restoration, the glazing process

(including cooling) is only about 7:30. Another great feature of

the CEREC SpeedFire is its incredibly small footprint. It can be

set on any table or countertop like any other oven. To top it all

off, it communicates wirelessly with the CEREC software as a

device. Based on what you are doing, the CEREC software auto-

matically transfers the proper cycle to the oven after the resto-

ration is milled!

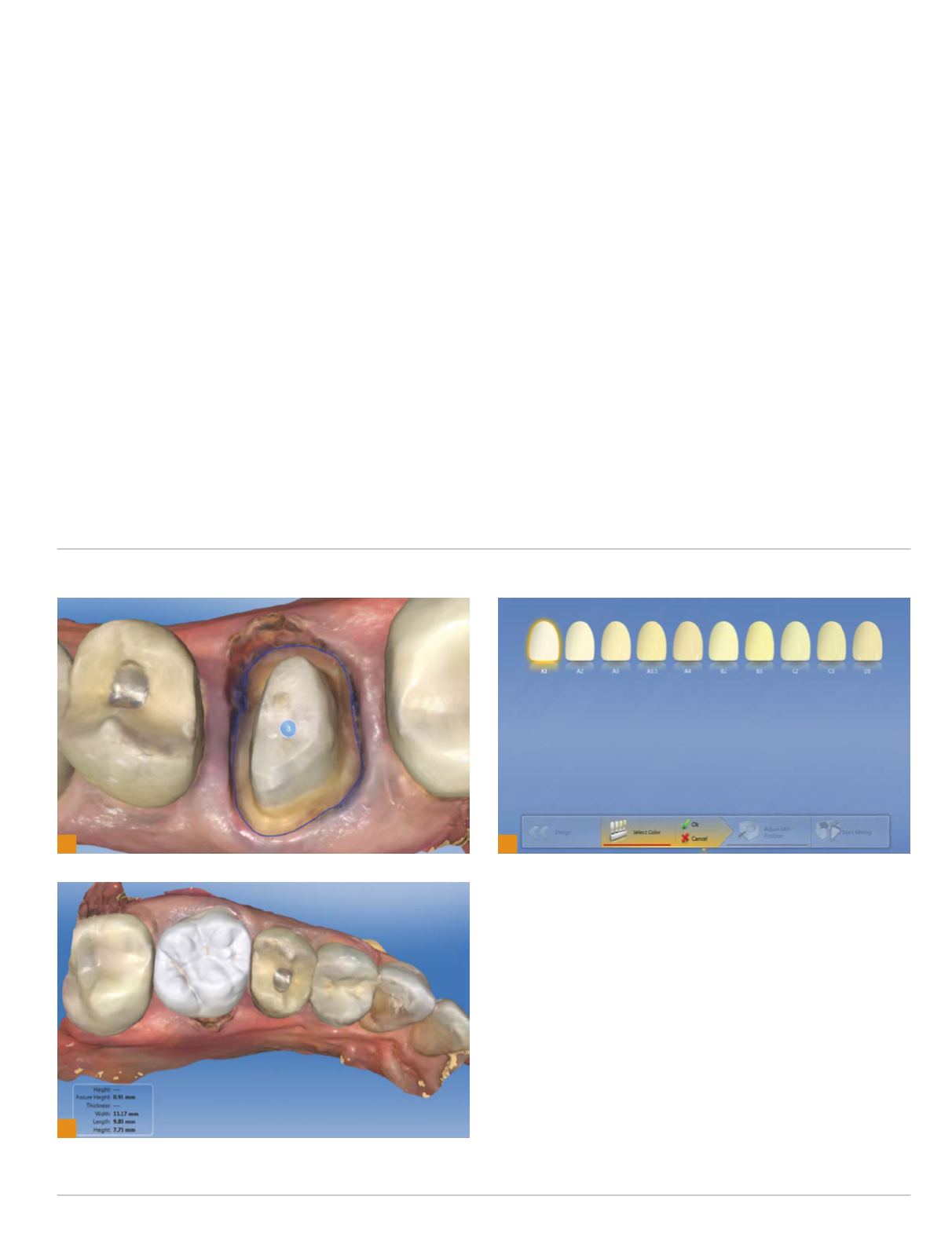

fig. 4:

The preparation was marginated in the 4.4.1 software.

Note that a deep chamfer margin design was used, the lack of

enamel, and how subgingival the margins are, reinforcing the

decision for a cementable restoration.

fig. 5:

Initial Biogeneric proposal. Note the excellent anatomy and

the fissure thickness of .91mm. Two advantages of using zirconia is

that it can bemilled a little thinner and, because it uses fine finishing

carbides andmilled roughly 20 percent larger, themilled anatomy

will bemore defined that traditional CEREC ceramics.

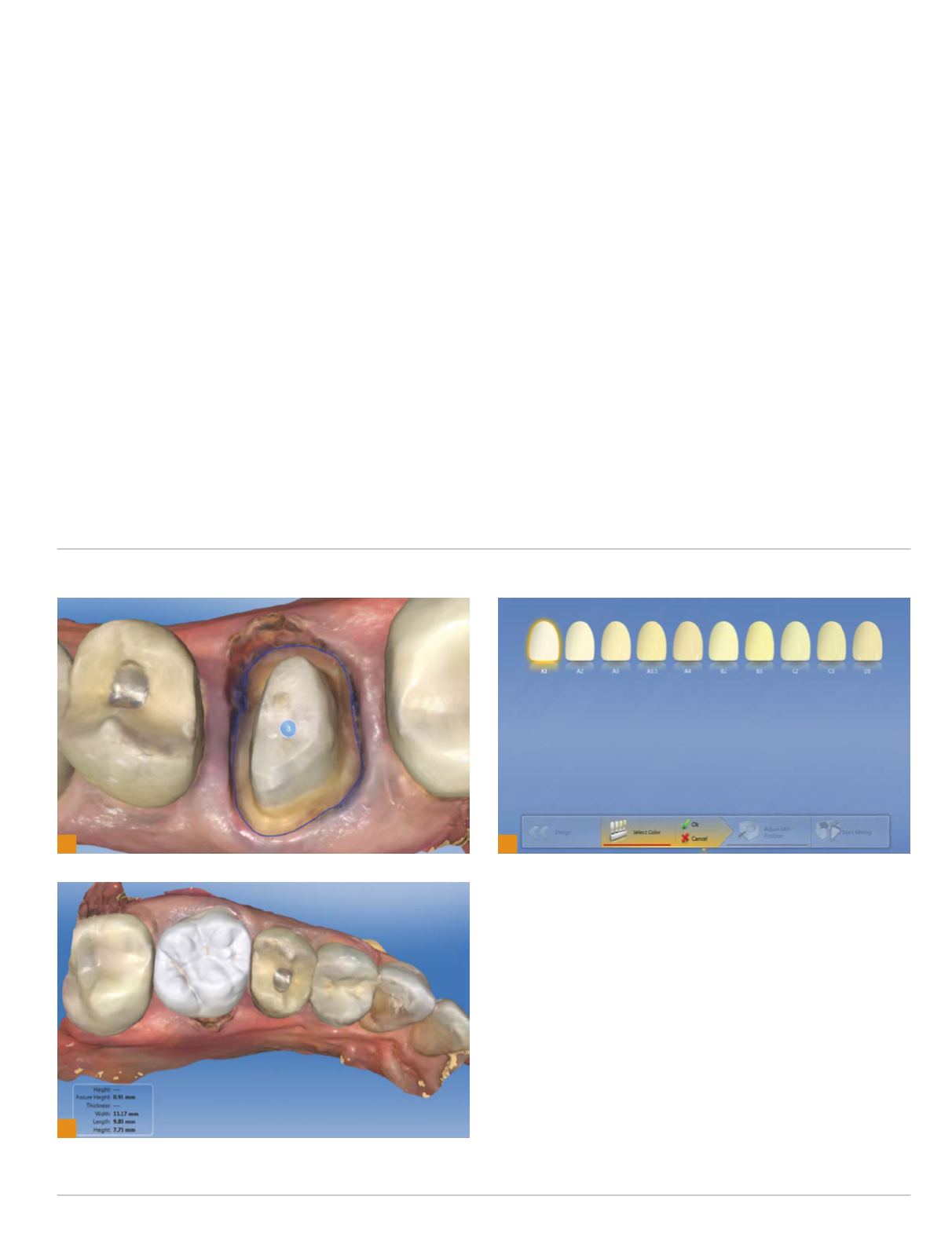

fig. 6:

When you go to theMill Preview, you will be prompted to

choose the final shade of the zirconia restoration. This shade

information will have a direct effect on the firing times in the

CEREC SpeedFire furnace.

4

5

6