30

|

CERECDOCTORS.COM

|

QUARTER 1

|

2016

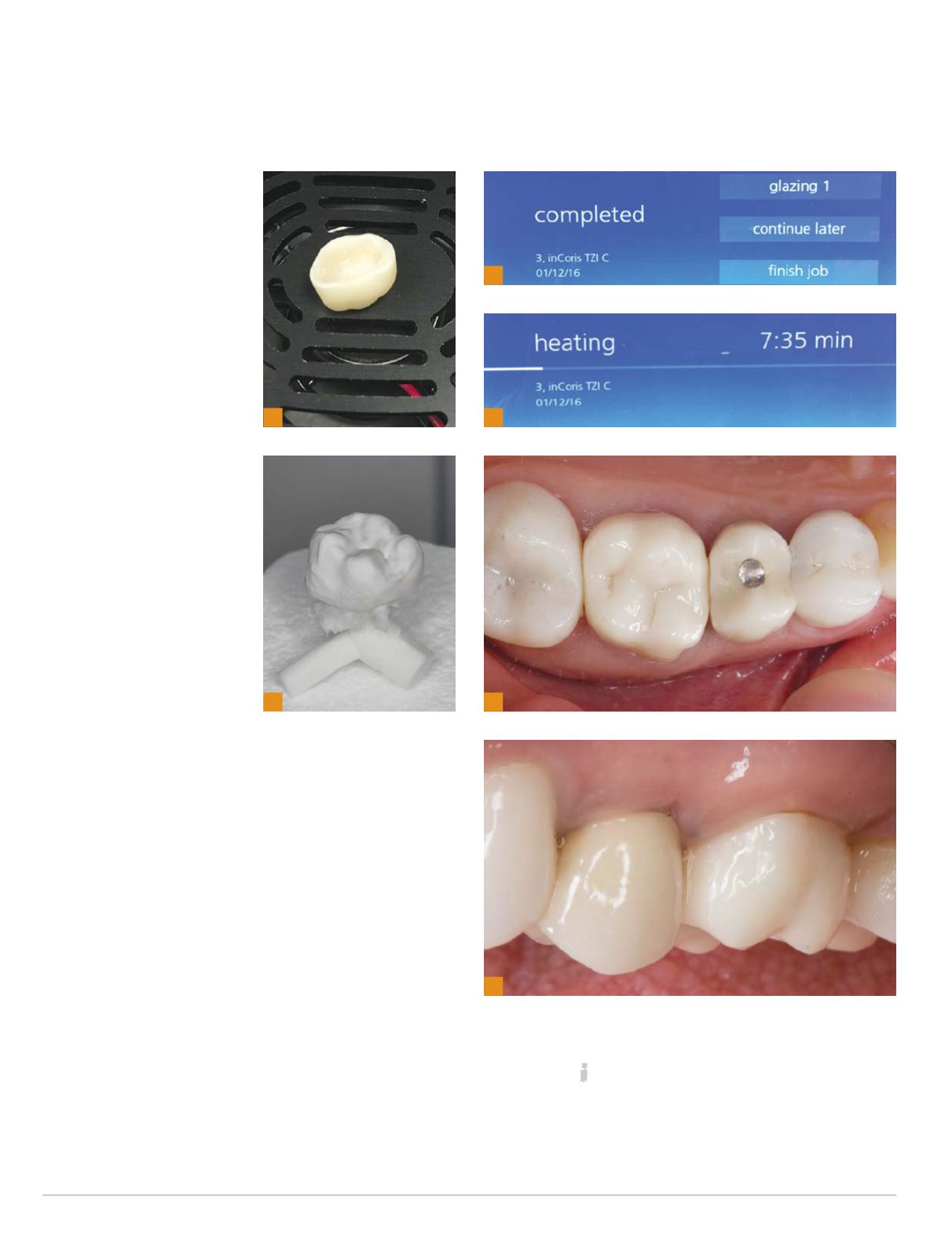

fig. 19:

After the sintering

process is complete, the

restoration is placed on a

small fan in front of the unit

for a minute to finalize the

cooling process.

fig. 20:

After the sintering, the

furnace will prompt you for

the next step. You can glaze

the restoration immediately

(indicated for same-day

restorations), continue the

glazing at a later time if

you wish (the furnace will

remember the job), or finish

the job in scenarios in which

you are not going to glaze.

fig. 21:

The restoration was

characterized with GC Lustre

Paste and spray-glazed with

Sirona SpeedGlaze

(a new product introduced

by Sirona for this workflow).

It is advisable that you

support the restoration on

a firing peg for this step to

prevent getting glaze on the inner surface of the restoration.

fig. 22:

The glaze time for this restoration was just under 8 minutes

(including cooling time)

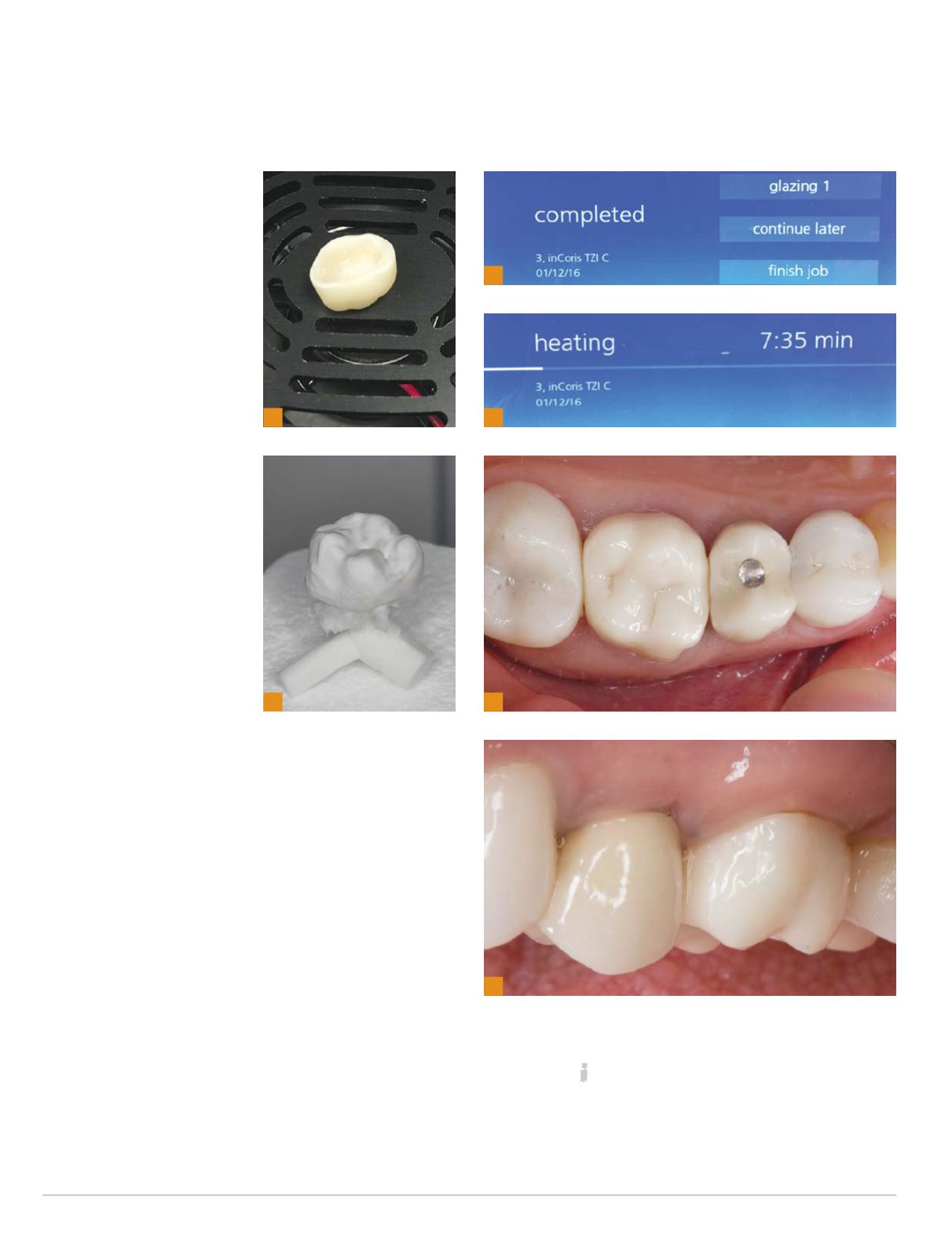

fig. 23:

Final cemented TZI C restoration occlusal view. Note the

color match and the nice anatomy resulting from the carbide milling.

fig. 24:

Final cemented TZI C restoration, buccal view. Please note

how the zirconia restoration blends with the existing arch.

SUMMARY

The ability to fabricate chairside zirconia restorations has many

benefits that have been described in this article. The most impor-

tant is clinical flexibility. This new workflow allows us as CEREC

users to expand our clinical environment and treat all patients in a

predictable matter. My personal experience with this process has

been eye-opening and I have been amazed at the clinical margins

and occlusal accuracy.

The restoration in this article was completed in an appointment

of 1.5 hours. Who would have ever imagined this possibility?!

NOTE: Please visit

for an new section

on this chairside zirconia workflow with both software and live

clinical videos.

For questions and more information, Dr. Skramstad can be reached

at

.

19

21

20

22

23

24