72

|

CERECDOCTORS.COM

|

QUARTER 1

|

2016

| | |

D I S C U S S I O N F O R U M

DOUGLAS SMAIL, OMFS

Great looking case!

I guess my kids won’t get any X-mas presents,

Daddy needs a mill next year!

JEREMY HELDT

Nice case Marko, thanks for sharing. Did

you immediately provisionalize as well?

Also, based on my limited understanding of CEREC

Guide 2, I was wondering how it would be possible to

do a small edentulous space like #25. Since the Guide

2 requires a minimum diameter space to accommodate

the sleeve, I’m pretty sure it wouldn’t fit in a #25 eden-

tulous space for a guide. Would a supra-occlusal placed

sleeve be an indication for that type of case as well?

ERIC PROUTY

Perhaps, yes, Jeremy, and if the drill doesn’t

go to length at least it gets you started at the

right angle.

FARHAD BOLTCHI (FACULTY)

@ Jeremy: Yes, you can use a supra-occlusal

sleeve position to solve the two situations you

are alluding to (immediate implant placement, narrow

spaces). However, as Mike mentioned above, you would have

to have long drills and then use the Verban Drill Stop tech-

nique (which I describe in detail in the third Academy online

webinar), or place a shorter implant or just get your drilling

started and do the rest free-hand.

@Ross and John: In some software (such as Co-Diagnostix

and BSP) the guide is designed in the implant planning soft-

ware and there are tools within those software programs to

virtually “extract” a tooth.

SICAT can obviously do this as well, but I don’t know if they

do it in their “master Galaxis” software or in their CAD soft-

ware. In our situation, the guide is designed in our CAD soft-

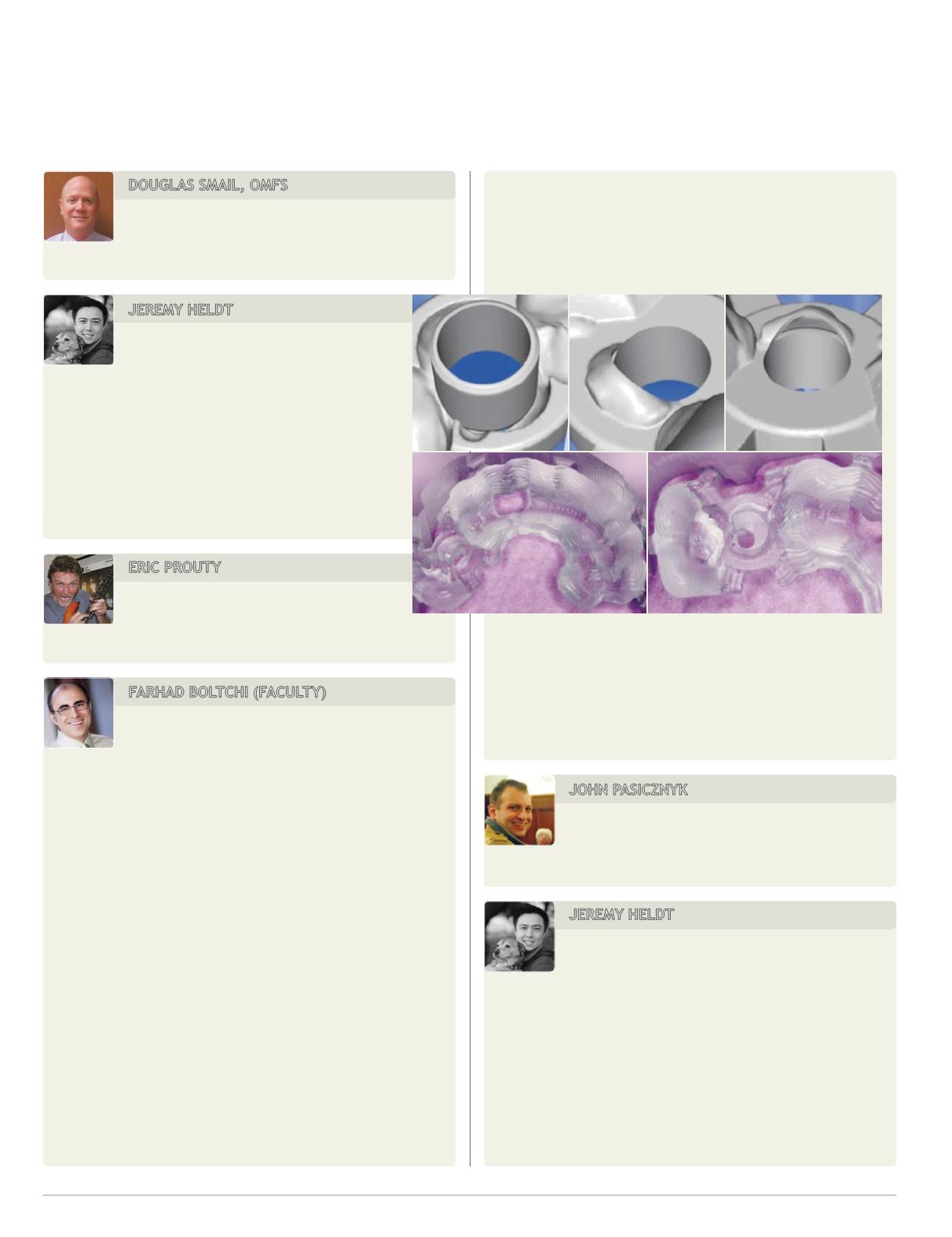

ware: i.e., the CEREC SW4.4. If you put the sleeve where there

is a tooth on the virtual model, then the software thinks it has

to mill both the sleeve and also mill the guide such that it fits

over the existing tooth since the software doesn’t know that we

will be extracting the tooth. The mill will start milling fine until

it gets to the part it has to mill the sleeve and the part of the

guide that fits over the tooth (which the software thinks will

still be there), then it will error out (typically indicating that the

carbide burs are defective). I wasted four blocks and four sets

of carbide burs trying this out during my testing (

photos below

).

It’s a different story with a subgingival or subcrestal sleeve

position. In that scenario, the software will alert you that there

is an intersection between the model and the guide sleeve. You

then have the option in the software to grind the sleeve support

out (if you want to do the case flapless for example) or to leave

it (and flap the case). Either way the guide will mill out fine.

JOHN PASICZNYK

Thanks for the explanation, Farhad. Makes sense I

guess. I’ll play around with virtual extraction and

see if I can make that work for these cases.

JEREMY HELDT

Completed our first Guide 2 case today! Seems like

it came out well. (Note: I have the Nobel Guided

Surgery kits with drill stops). The Sirona sleeves were pretty

tight and had to work a little to get them in and out, but I guess

tight is what you want them to be anyway to reduce error. The

onlycautionwiththat is theguidesleevesSironamakesare fairly

pliable and could get bent, and possibly even break off when

removing from the Guide 2. Maybe they did this on purpose for

situations that might need some bending? Placing the sleeve

supra-occlusally for the extract and immediate worked and